/

Discrepancies Report

Discrepancies Report

Discrepancies Report Solutions:

The report will show two basic sections:

- Inventory Items: Shows the details of all the boxes that are in the system's inventory, but were not scanned with the scan gun during the physical inventory process.

- Physical Overage: Shows the details of all the boxes that were scanned physically but were not in the system's inventory.

Inventory Items:

- The warehouse should be checked thoroughly to ensure the box is not there and it was not missed in the scanning process.

- If the box is not located there is a chance the wrong product was dispatched or the box is missing.

- It is recommended to check the Physical Overages section to see if similar products that were previously sold but not dispatched are appearing in this section. If similar products are found, there is a chance that the wrong product was dispatched to the client and the correct one was left behind. If this happens it is recommended to adjust the invoice order to reflect the actual product shipped, and to scan the product that was left behind back into your inventory.

- It the box can't be found, it must be billed to the "Inventory Adjustments" account with a $0 price with a past date. Next time, the inventory count is done this box will not appear in the Discrepancies Report.

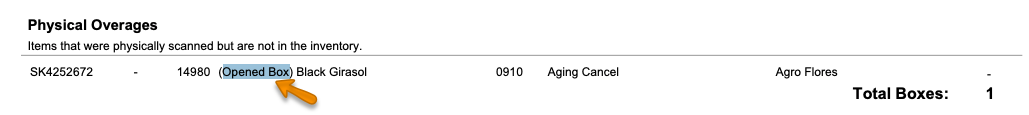

Physical Overages

- If boxes from a previous order are found in the warehouse, two scenarios may have happened: a.) Either the salesperson never confirmed the order or confirmed it after the truck date. Therefore, the boxes were not sent to the client. If this is the case, the order's date must be updated in order to ship and scan the correct box; or the order can be canceled so the boxes return to the inventory. These boxes can be identified as the product information and the order's information coincide. b.) Another possibility is an error in the shipping process; either the box was scanned twice or the label was incorrectly scanned. In this case, the aforementioned in point 3 may apply.

- If boxes are found physically and are not in the system, they must be checked to ensure they are inventory boxes or if they have been scanned incorrectly. If it is determined that they belong to the inventory, they must be manually added to the inventory and labels must be reprinted in order to scan them again. These boxes can be identified as their box number and position appear on the report, but no other information exists.

In the previous case, the box can be scanned again and the system will remove it from the discrepancies section and add it to the inventory.

Boxes Opened

Boxes opened may appear in the physical overages section as discrepancies:

, multiple selections available,

Related content

Reports in Koronet Payments

Reports in Koronet Payments

More like this

Inventory Count

Inventory Count

More like this

Unit Inventory Management

Unit Inventory Management

More like this

Print Labels for Delaware Valley

Print Labels for Delaware Valley

Read with this

Sell By Units in E-commerce

Sell By Units in E-commerce

More like this

Vendor Availability Screen

Vendor Availability Screen

More like this